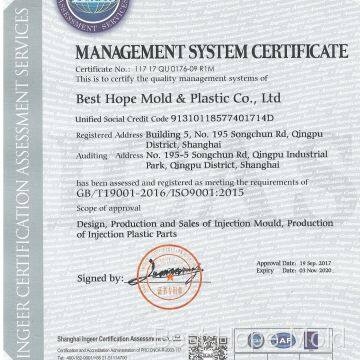

BHM is ISO9001 certified and we strictly implement ISO standard, adhere tothe management theory of quality first.

We pay close attention to every detail of our products. Our in-depth knowledge, craftsmanship and experience in production have helped our product be very popular.

AT BHM MOLDING YOU WILL SEE WE CONTROL MOLDING QUALITY FROM FOLLOWING ASPECT

INSPECTION TOOLS IN BHM:Caliper, CMM (Coordinate Measuring Machine) Dial Indicator,Filler Gage,Gage Block,Height Gage, Micrometer, Pin Gage,Protractor, Radius Gage, Ring Gage, teel Rule, and scope.